Pressure Testing

Independent QA/QC can perform or witness piping system pressure tests which provide the owner assurance that all test parameters meet ASME B31.3 requirements as well as project specifications. Independent QA/QC has the capabilities to perform both hydrostatic as well as pneumatic pressure testing of piping system and components. Our team possess a thorough understanding of all types of piping systems (metallic and non-metallic) and related fluid service categories as defined in ASME B31.3. This comprehensive understanding is translated into the highest level of safety while performing pressure tests in order to protect personnel as well as the owner’s equipment and facilities. All pressure test gauges and transducers utilized by Independent QA/QC are calibrated yearly to NIST traceable calibration standards. Test gauges are of parallax (mirror back) design with 1 psig pressure graduations. Pressure gauges and transducers can be provided in a variety of pressure ranges and graduations to meet our customer’s requirements.

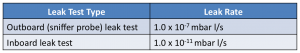

Helium Leak Testing

Independent QA/QC has the capability to perform inboard and outboard mass spectrometry helium leak detection on a variety of stainless steel process gas, chemical and vacuum systems as well as distribution equipment and process tools. Mass spectrometry helium leak detection provides the owner not only with an increased safety factor over and above that provided by pressure testing alone but it also insures that process systems are free of atmospheric leak paths resulting in the delivery of the highest quality process materials at the point of use. Independent QA/QC utilizes a variety of helium leak detectors manufactured by Alcatel and Inficon. All leak detectors are calibrated on site daily (at a minimum) with calibrated leak sources that are traceable to NIST calibration standards. Mass spectrometry helium leak testing is capable of detecting leak rates down to the following levels:

Click on image to increase size